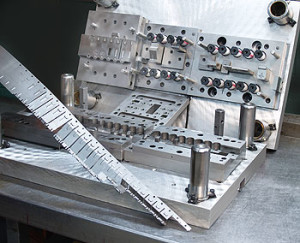

Progressive Die Stamping

At Atlantic Precision Spring, we specialize in designing and manufacturing progressive die stamping tools for various industries. Our precise attention to detail ensures complete customer satisfaction throughout the progressive die stamping process.

From aerospace to automotive, medical, and electrical, we are experts in producing high-quality metal stamped parts for various applications. Whether you require complex metal components or simple stamped pieces, our team can handle all your progressive die stamping projects with precision and efficiency.

Our high-speed power presses, ranging from 25 to 100 tons, enable us to deliver precise and efficient progressive die stamping solutions. Equipped with state-of-the-art equipment, our presses ensure high accuracy and versatility, allowing us to meet tight tolerances and demanding specifications.

We offer a broad array of stamping services, including forming, in-die tapping, deep drawing, fine blanking, thin drawing, and extruding, making manufacturing various metal stamping tools possible.

Our packaging options are flexible to meet your needs, whether you require bulk orders or individual packaging like bag-and-tag orders. Additionally, we provide value-added services like heat treating and plating through our trusted network of approved vendors.

Benefits of Progressive Dies in Stamping:

High-Speed Production: Progressive dies enable fast, efficient production, making them ideal for large-volume runs and reducing manufacturing time.

Close Tolerances: These dies are designed to operate with precision, ensuring that every part meets strict tolerance requirements, which is crucial for industries like aerospace, automotive, and medical.

Multiple Parts Per Stroke: Progressive dies can produce various parts in a single stroke, maximizing output and improving production efficiency.

Long Tool Life: With powered metal and carbide tools, progressive dies offer enhanced durability, ensuring a long tool life and reducing maintenance costs.

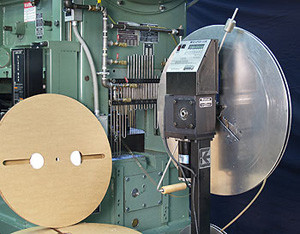

Reel to Reel

At Atlantic Precision Spring, we offer reel-to-reel progressive die stamping to streamline our customers’ manufacturing process. This method enables the pick-and-place automated assembly in your facility, improving efficiency and reducing labor costs.

Reel-to-reel packaging involves winding a continuous strip of breakaway parts with an interleave of protective paper, which prevents tangling and ensures the integrity of the product throughout handling and shipping. This process is ideal for high-volume production runs where precision and consistency are key.

Our 75-ton Minster Power Press is capable of producing metal stampings from flat strip material ranging from .003″ to .125″ thick and up to 12″ wide. We work with a variety of materials, including:

- Aluminum

- High and low-carbon steel

- Stainless steel

- Beryllium copper

- And more…

Whether you need progressive metal stamping parts for aerospace, automotive, or medical applications, we can deliver high-quality stamped components to your exact specifications.

At Atlantic Precision Spring, we are committed to quality and precision in every project. Our advanced equipment and expert team ensure that we consistently meet our customers’ high expectations—every single time.

What Is Progressive Die Stamping?

Progressive die stamping is a metal forming process that offers high-speed production, operates to close tolerances, can produce multiple parts per stroke, and is powered metal and carbide tools that have a long tool life.

What Is The Progressive Tool and Die Process?

The progressive tool and die process at Atlantic Precision Spring includes precise attention to detail throughout every step of the way. Our state-of-the-art equipment is highly accurate and versatile, able to easily handle tight tolerances.