Metal Stamping Materials

There are many materials that can go into making flat springs, battery spring contacts, metal stampings, springs, and wire forms. Atlantic Precision Spring boasts the material capabilities to work with them all. No matter what material your application calls for, our engineering staff possesses excellent knowledge about its strengths, weaknesses, and best utilization.

Atlantic Precision Spring has mastered the art of material manipulation. If it can be stamped, twisted or bent – we are the experts you need.

Beryllium Copper

Beryllium Copper

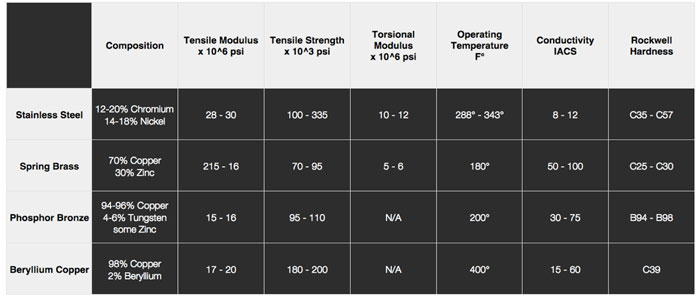

Beryllium copper is one of the best and most popular materials for making electrical spring contacts. There are a few reasons for this. Its material properties allow for a wide range of spring travel without it taking a set. That is, it has a very “springy” makeup. Along with that, it’s also an excellent conductor of electricity (depending on the finish) which is crucial for electrical spring contacts.

Carbon Steel

Carbon steel is the most economical material for creating a spring. It can be formed, heat-treated and plated at a lower cost than Beryllium Copper.

Phosphor Bronze

Phosphor bronze makes for a tough, strong flat spring. One thing to keep in mind, though, is that the material is pre-tempered, making it somewhat brittle. This attribute reduces the size of its bend radii and limits its forming potential.

Brass

Brass is used for various applications such as making gears, bearings, and slide plates, which all call for a smooth surface and low friction. Brass is a softer material than most other metals.

Nickel

Nickel possesses good corrosion-fatigue and strength resistance. It also boasts a high resistance to cracking or breaking.

Aluminum

Aluminum is a light metal with low density and solid corrosion resistance. These attributes make aluminum one of the aerospace industry’s most widely used metals. Aluminum is available in many alloys that are each designed to work best for specific chemical compositions and applications.

Inconel

Inconel is difficult to shape and weld, but it excels in extreme environmental conditions. It’s a material that is usually used in high-temperature applications and industries such as firearms, military, and aerospace.

Stainless Steel

Stainless steel is a commonly used metal for many applications because it does not require a finish to prevent oxidation, tarnish, or rust.

Nickel Silver

Nickel silver alloy is great for making contact springs. It has a high electrical resistance and strongly resists corrosion.

Bimetals

Bimetals, as the name implies, are a combination of two metals joined together. Unlike alloys, which are mixed, bimetallic objects layer the two metals. Bimetals are great for reducing the overall cost of parts requiring precious metals like gold and silver.