Atlantic Precision Spring specializes in the design and build of progressive die stampings for large volume orders. Our attention to detail in the creation of each step in the progressive die assures that customers receive complete satisfaction, knowing that the metal stampings will meet or exceed expectations.

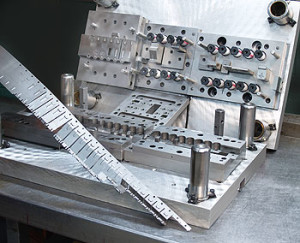

Progressive Dies

Every progressive stamping tool can be set up in our power presses ranging in size from 25 to 100 tons for high-speed part production. All tools are designed and built in-house using the precise state-of-the-art equipment that can handle customers’ tight tolerances. Many styles of parts can be manufactured at Atlantic Precision Spring utilizing progressive die stamping tools including:

- Forming, In-Die Tapping, Deep Drawing

- Fine Blanking, Thin Drawing, Extruding

We offer packaging of metal stampings from bulk to bag and tag according to specific needs. Additional services include heat treating and plating through our network of approved vendors. We also offer high-speed production, operate to close tolerances, and can produce multiple parts per stroke.

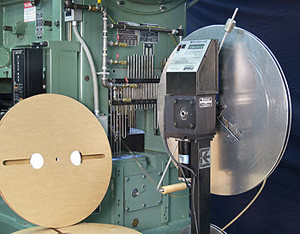

Metal Stamping with Reel-to-Reel Capabilities

Reel-to-reel packaging of progressive die stamping products makes it possible for our customers to use pick-and-place automated assembly in their manufacturing facility.

The ribbon of breakaway parts is wound on a continuous strip with a paper interleave that protects the product and eliminates tangling. Our equipment can produce metal stampings from flat strip: .003″ to .125″ thick & up to 12″ wide.

Materials of all grades and tempers, including:

- Aluminum

- High/Low Carbon Steel

- Stainless Steel

- Phosphor Bronze

- Brass

- Nickel

- Bimetals

- Beryllium Copper

- Precious Metals